RIO TINTO IRON ORE CASE STUDY 2

MAJOR WATER Infrastructure

BACKGROUND

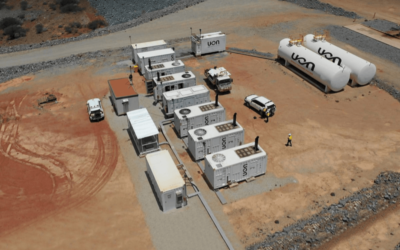

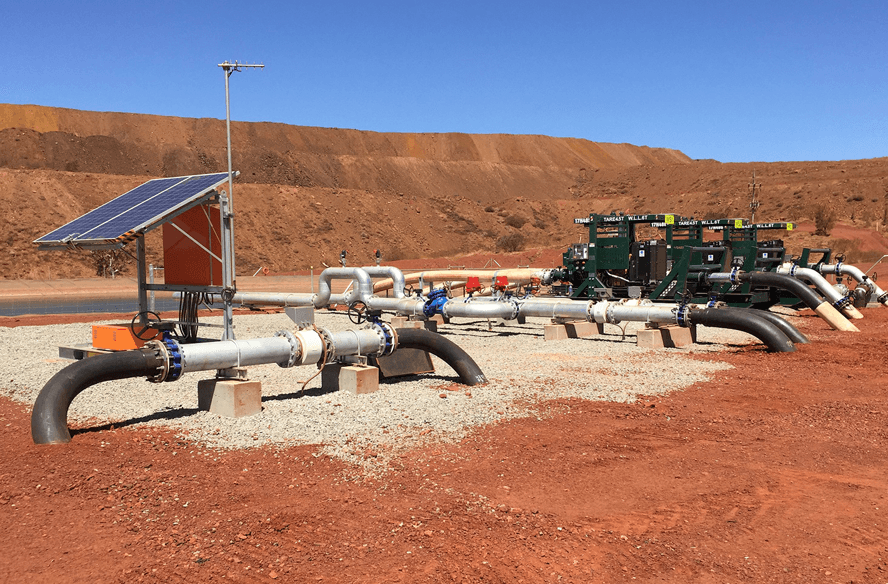

UON were tasked by Rio Tinto to design, supply, install and commission bore pumps, generators, telemetry and associated equipment.

Team Members

Pieces of equipment

Hours worked LTI-free

Pilbara

Region

RIO TINTO

Client

IRON ORE

Commodity

PURCHASE

Contract

KEY SUCCESS

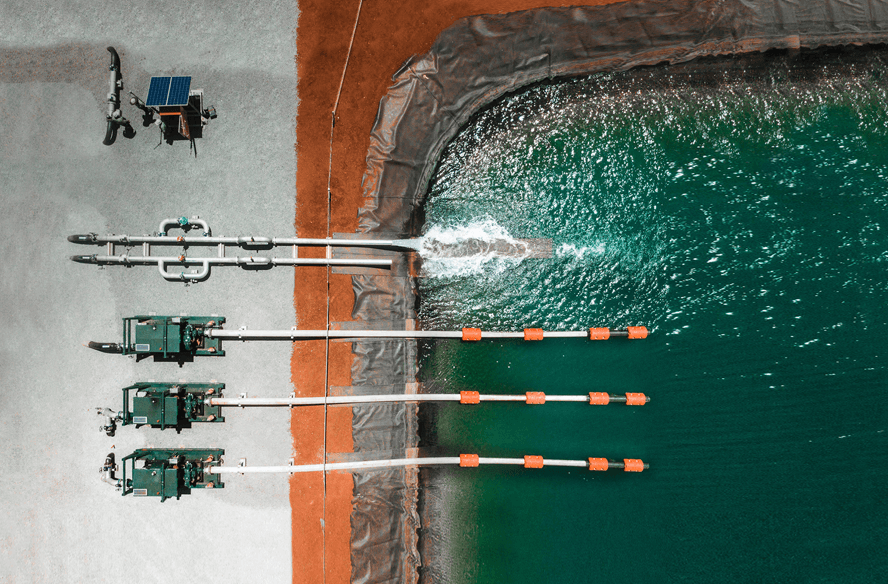

UON successfully delivered and commissioned 7 in-pit dewatering packages, turkey’s nest, sedimentation basins, pumping station, HDPE pipeline connections and additional dewatering resources to sustain operations at its open iron ore pit.

DELIVERABLES

- 11 x 300kvA GMC Generator on Trailer

- 4 x 200kvA UON GMC Generator on Trailer

- 6 x 250kvA UON GMC Generator on Trailer

- 3 x 150kvA UON GMC Generator on Trailer

- 18 x 4000L UON Fuel Tanks

- 16 x 92 to132kW Downhole Bore Pump Packages

- 6km of HDPE

- Steel Manifold Pipework and Valves

- Hydro Testing, Installation & Commissioning

- Delivered On-Time and In-Budget

OTHER PROJECTS

Novo Gold Case Study 1

Supply and Installation of Power Station for Underground Mining

FMG Iron Ore Case Study 1

The FMG magnetite iron-ore mine was a new trial mine.

Dacian Gold Case Study 1

The key success of the rapid-deployment 6 MW / 11 kV power station was the modularization and flexibility of all equipment provided as part of UON’s complete solution

Bellevue Gold Case Study 1

UON were tasked with delivering a dewatering solution for an old mine being reactivated, via an existing ventilation shaft.

Adaman Gold Case Study 1

UON was contracted to design, manufacture and install a pontoon system to dewater over 7 Billion litres from an old open pit mine.

BHP Case Study 3

The key success of the Rapid-Deployment 30MW Power Station was UON’s time management and orchestrated scheduling of people and plant.

GET A PROMPT RESPONSE

"*" indicates required fields