Dacian Gold Case Study 1

at6 MW POWER STATION 11kv

BACKGROUND

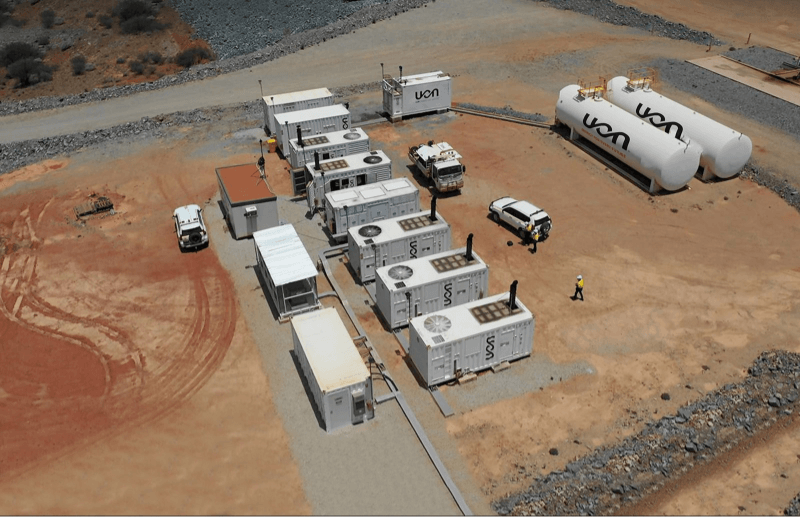

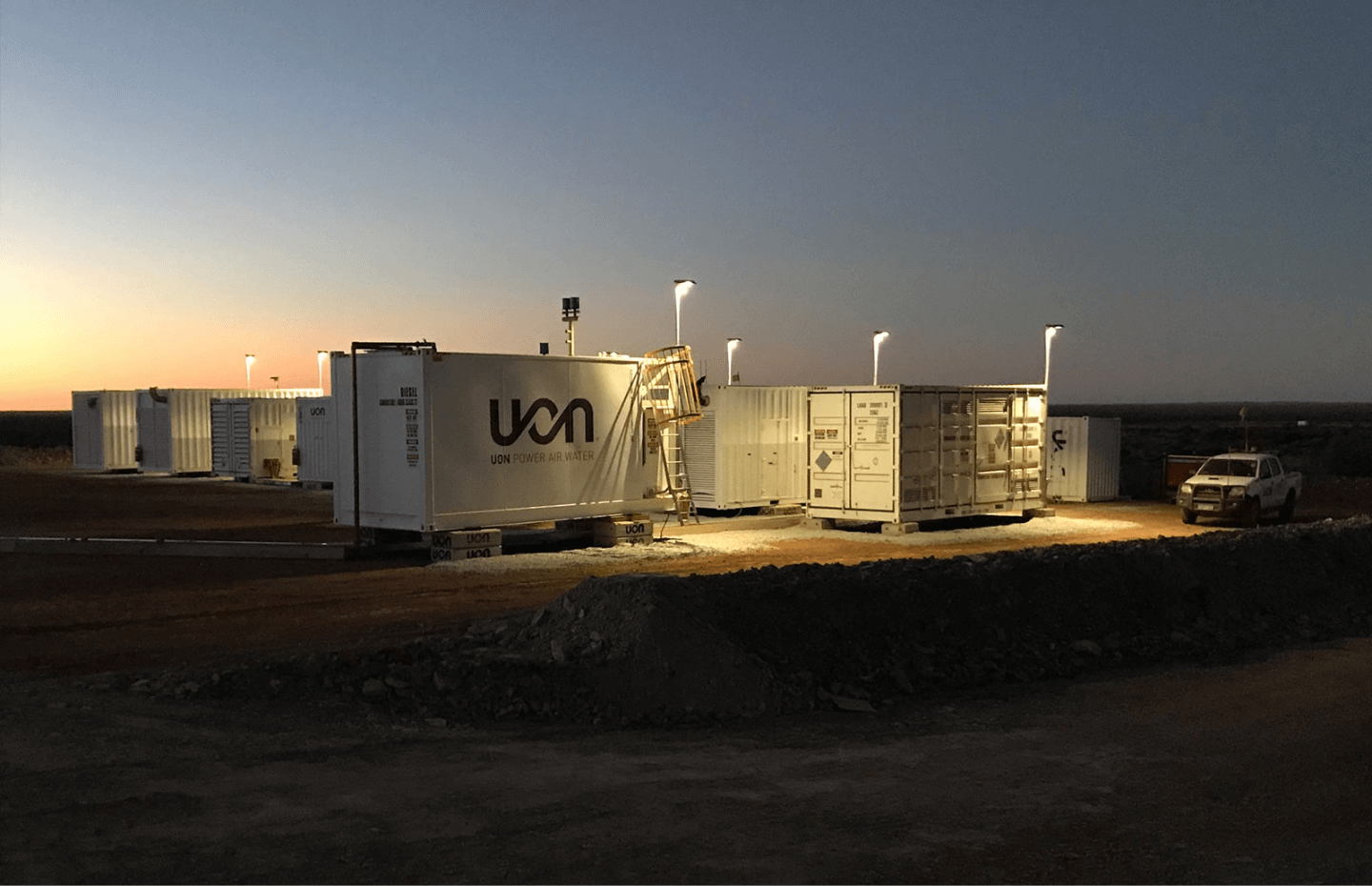

UON were engaged to design, supply, install, test and commission a turnkey 6 MW / 11kV power station including remote monitoring, enabling development of a new underground mine. This was a BOOM operation (Build, Own, Operate and Manage) where the power station would be installed without the capital expenditure associated with purchasing the infrastructure.

Team Members

Pieces of equipment

Hours worked LTI-free

MW Installed

Goldfields

Region

Dacian

Client

GOLD

Commodity

Boom

Contract

KEY SUCCESS

The key success of the rapid-deployment 6 MW power station was the modularization and flexibility of all equipment provided as part of UON’s complete solution, whilst meeting stringent mining specifications. This in turn minimized client interaction, client site resources and resultant client cost.

DELIVERABLES

UON deployed electric pumps powered by our GMC generators to deliver over 30% fuel savings compared to competitors.

- 6 modular diesel generators

- Modular 415V / 11 kV substation

- 11 kV switch room

- 120 kL fuel storage

- On-site office and remote monitoring

- All design, construction, commissioning, operation and decommissioning

OTHER PROJECTS

Novo Gold Case Study 1

Supply and Installation of Power Station for Underground Mining

FMG Iron Ore Case Study 1

The FMG magnetite iron-ore mine was a new trial mine.

Bellevue Gold Case Study 1

UON were tasked with delivering a dewatering solution for an old mine being reactivated, via an existing ventilation shaft.

Adaman Gold Case Study 1

UON was contracted to design, manufacture and install a pontoon system to dewater over 7 Billion litres from an old open pit mine.

BHP Case Study 3

The key success of the Rapid-Deployment 30MW Power Station was UON’s time management and orchestrated scheduling of people and plant.

BHP Case Study 2

UON were tasked to Supply, Manufacture and Install Major Dewatering Works and Transfer System.

GET A PROMPT RESPONSE

"*" indicates required fields