Novo Gold Case Study 1

POWER SUPPLY AND DEWATERING

BACKGROUND

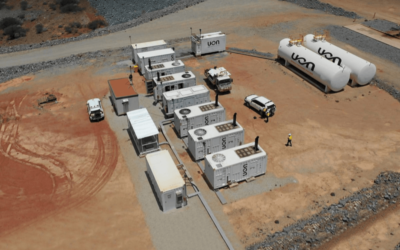

UON was contracted to supply “whole of mine” power and dewatering services for Nova Resources. This included managing a bore field that spanned over 100km with integrated pipework and a network of open pits that required dewatering as well. The operation required a dynamic approach. UON deployed permanent back-to-back technicians onsite to provide continuous operations and ensure that the mine site had continuous flow of water and delivery of power.

Team Members

Pieces of equipment

Hours worked LTI-free

Pilbara

Region

NOVO Resources

Client

Gold

Commodity

Boom

Contract

DELIVERABLES

- 40+ generators ranging from 8 kVA to 500 kVA.

- Multiple submersible bore pump pontoon’s utilizing GMC Technology

- Multiple diesel pump skids/trailers for mobile dewatering.

- Telemetry over vast distances.

- B.O.O.M 2.5 MW power station for underground mining operation.

- 24/7 onsite technical support.

- Light truck and multiple light vehicles.

OTHER PROJECTS

FMG Iron Ore Case Study 1

The FMG magnetite iron-ore mine was a new trial mine.

Dacian Gold Case Study 1

The key success of the rapid-deployment 6 MW / 11 kV power station was the modularization and flexibility of all equipment provided as part of UON’s complete solution

Bellevue Gold Case Study 1

UON were tasked with delivering a dewatering solution for an old mine being reactivated, via an existing ventilation shaft.

Adaman Gold Case Study 1

UON was contracted to design, manufacture and install a pontoon system to dewater over 7 Billion litres from an old open pit mine.

BHP Case Study 3

The key success of the Rapid-Deployment 30MW Power Station was UON’s time management and orchestrated scheduling of people and plant.

BHP Case Study 2

UON were tasked to Supply, Manufacture and Install Major Dewatering Works and Transfer System.

GET A PROMPT RESPONSE

"*" indicates required fields