ADAMAN GOLD CASE STUDY 1

PONTOON PUMPING STATION

BACKGROUND

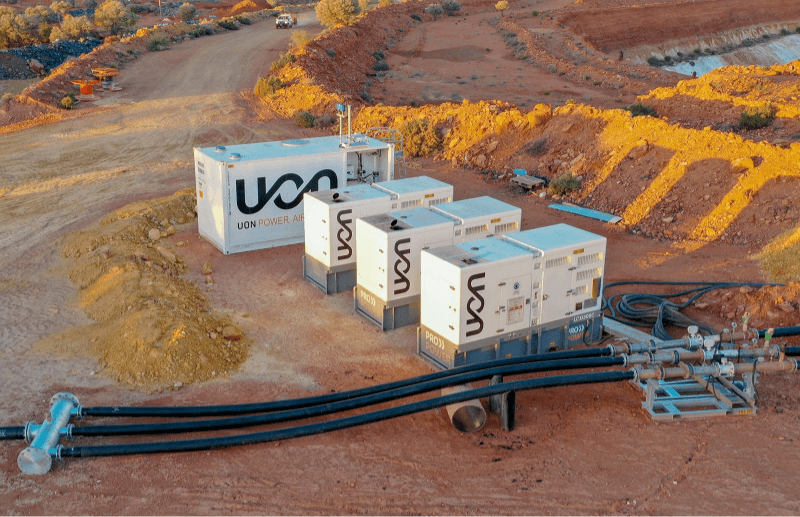

The client required the ability to vary the flow of the water due to the complexities of disposal capacity. The variable speed ability of the generators granted the client flexibility to manage their water demand to suit the environmental conditions.

Hours worked LTI-Free

Pieces of equipment

Billion Litres of Water

Months

Mid West

Region

ADAMAN

Client

GOLD

Commodity

RENTAL

Contract

KEY SUCCESS

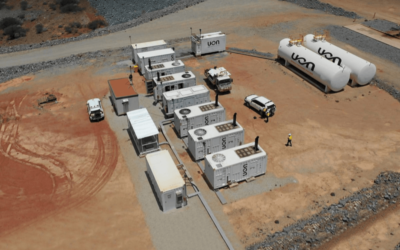

UON was contracted to design, manufacture and install a pontoon system to dewater over 7 Billion litres from an old open pit mine within 12 months. The key success of the Pit Dewatering Works was the use of UON’s patent-pending GMC unit for total pumping control where pit access and logistics is challenging.

DELIVERABLES

UON deployed electric pumps powered by our GMC generators to deliver over 30% fuel savings compared to competitors.

- 3 x 300kVA GMC Generators

- 3 x 147kW Pumps

- 3 x UON Modular Pontoon Systems

OTHER PROJECTS

Novo Gold Case Study 1

Supply and Installation of Power Station for Underground Mining

FMG Iron Ore Case Study 1

The FMG magnetite iron-ore mine was a new trial mine.

Dacian Gold Case Study 1

The key success of the rapid-deployment 6 MW / 11 kV power station was the modularization and flexibility of all equipment provided as part of UON’s complete solution

Bellevue Gold Case Study 1

UON were tasked with delivering a dewatering solution for an old mine being reactivated, via an existing ventilation shaft.

BHP Case Study 3

The key success of the Rapid-Deployment 30MW Power Station was UON’s time management and orchestrated scheduling of people and plant.

BHP Case Study 2

UON were tasked to Supply, Manufacture and Install Major Dewatering Works and Transfer System.

GET A PROMPT RESPONSE

"*" indicates required fields