RIO TINTO IRON ORE CASE STUDY 1

MAJOR WATER Infrastructure

BACKGROUND

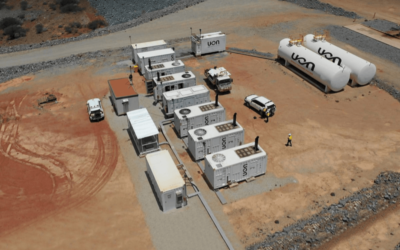

UON were engaged by Rio Tinto as the head contractor for the design, supply and construction works as detailed below. This extensive dewatering project has contributed greatly to the lower carbon footprint and commercial viability of this mine as a whole.

Team Members

Pieces of equipment

Hours worked LTI-free

Pilbara

Region

RIO TINTO

Client

IRON ORE

Commodity

D+C

Contract

KEY SUCCESS

During these projects UON achieved several key successes, with the number 1 success joining forces with the local traditional landowners, the Karuma people. UON have also been recognized by Rio Tinto for achieving 1 million-man hours LTI-free and received an award for Environmental Excellence on this project.

RIO TINTO IRON ORE CUT BACK

- Clearing and grading, topsoil strip, pipe supply & delivery, earth pinning, civil & earthworks, bore pad construction and concrete

- Installation of above and below ground HDPE Pipeline, valves, fittings bends, reducers support and connections

- Horizontal drilling

- Supply and installation of electrical cables, optic fibre, conduits and terminations

- Supply and installation of controls & communications

RIO TINTO IRON ORE WATER SUPPLY

- Clearing and grading, level corrections, topsoil strip, pipe supply & delivery, crossings, earth pinning and DMR Road and RTIO HDD shots

- Installation of HDPE pipeline connecting bore headworks to transfer tanks

- Supply and installation of transfer water storage tanks

- Installation of interconnecting HDPE pipe work between the transfer pumps and water storage tanks

- Supply and installation of electrical cables, optic fibre, conduits and terminations

- Supply and installation of controls and communications

RIO TINTO IRON ORE WATER SUPPLY

- Clearing and grading, topsoil strip, pipe supply and delivery, earth pinning, thrust blocks, bore pad constructions, concrete and crossings

- Wet plant haulage including 70,000 LCM pad material

- Micro tunnelling and horizontal drilling

- Supply and installation of transfer pump stations

- 20 KM above & below ground HDPE pipeline, valves and manifolds

- Steel pipeline, valves and manifolds

- Free-issued MCC’s

- Electrical substations and kiosk transformers

- Overhead powerlines and pole top transformers

- Electrical cables, optic fibre, conduits and terminations

- Controls and communications

OTHER PROJECTS

Novo Gold Case Study 1

Supply and Installation of Power Station for Underground Mining

FMG Iron Ore Case Study 1

The FMG magnetite iron-ore mine was a new trial mine.

Dacian Gold Case Study 1

The key success of the rapid-deployment 6 MW / 11 kV power station was the modularization and flexibility of all equipment provided as part of UON’s complete solution

Bellevue Gold Case Study 1

UON were tasked with delivering a dewatering solution for an old mine being reactivated, via an existing ventilation shaft.

Adaman Gold Case Study 1

UON was contracted to design, manufacture and install a pontoon system to dewater over 7 Billion litres from an old open pit mine.

BHP Case Study 3

The key success of the Rapid-Deployment 30MW Power Station was UON’s time management and orchestrated scheduling of people and plant.

GET A PROMPT RESPONSE

"*" indicates required fields