BHP IRON ORE CASE STUDY 2

Water Management Infrastructure

BACKGROUND

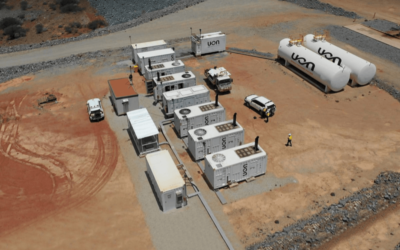

UON was engaged by BHP to supply, install and commission major dewatering infrastructure and transfer system for the new mining area.

Team Members

Pieces of equipment

Hours worked LTI-free

Pilbara

Region

BHP

Client

IRON ORE

Commodity

D+C

Contract

KEY SUCCESS

This extensive dewatering project has contributed greatly to the lower carbon footprint and commercial viability of this mine as a whole. The efficiency of the solution saved a considerable amount of fuel and allowed the accessing of the ore body in a timely manner.

DELIVERABLES

- 6 dewatering bores and downhole infrastructure

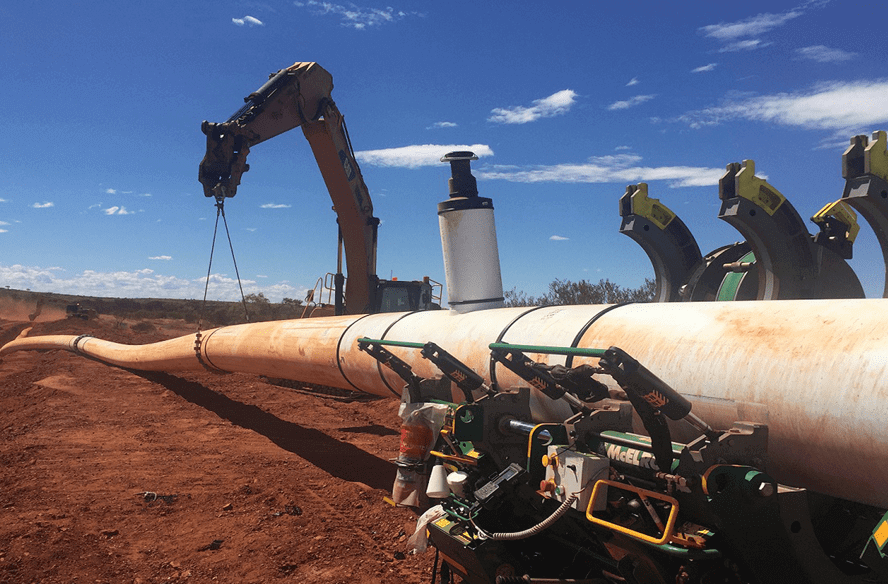

- 31km coextruded HDPE pipe including 25Km of DN710

- 10ML turkey nest dam including HDPE liner, associated pipe work and fencing

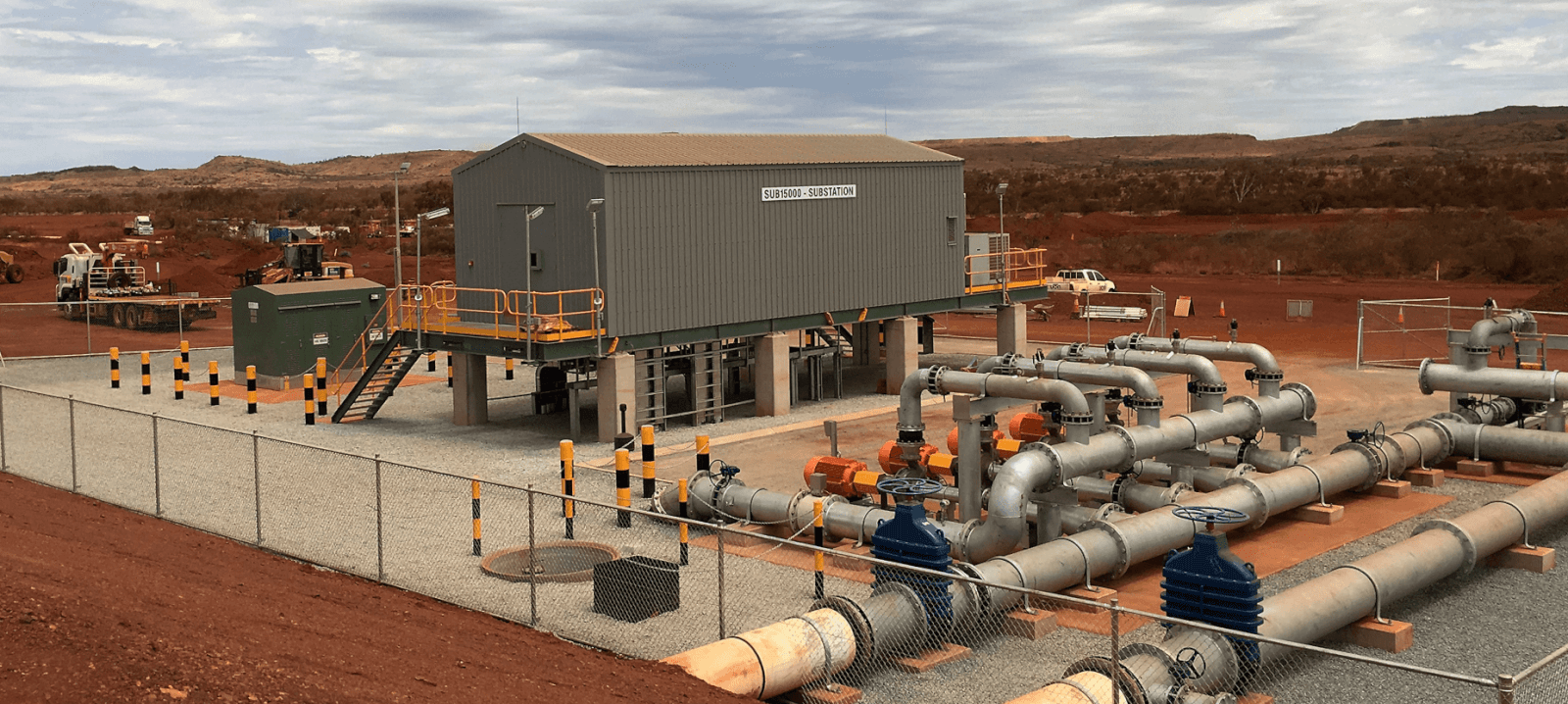

- Transfer pump station

- Standpipe pump station

- Flow monitoring station

- Switch room and control room

OTHER PROJECTS

Novo Gold Case Study 1

Supply and Installation of Power Station for Underground Mining

FMG Iron Ore Case Study 1

The FMG magnetite iron-ore mine was a new trial mine.

Dacian Gold Case Study 1

The key success of the rapid-deployment 6 MW / 11 kV power station was the modularization and flexibility of all equipment provided as part of UON’s complete solution

Bellevue Gold Case Study 1

UON were tasked with delivering a dewatering solution for an old mine being reactivated, via an existing ventilation shaft.

Adaman Gold Case Study 1

UON was contracted to design, manufacture and install a pontoon system to dewater over 7 Billion litres from an old open pit mine.

BHP Case Study 3

The key success of the Rapid-Deployment 30MW Power Station was UON’s time management and orchestrated scheduling of people and plant.

GET A PROMPT RESPONSE

"*" indicates required fields